undefined

[Excellent After-Sales] Yier Technology AT2000L Raise Borer Machine Aids in the Successful Penetration of Surface Shafts for the Guangdong Project of the Water and Electricity No. 9 Bureau.

Release time:

2024-11-29

The diameter of the expanded mining shaft is 2 meters, with a depth of 180 meters and an inclination angle of 90°. The geological layers at the construction site are primarily composed of metamorphic sandstone and gray-white granite, with an average rock hardness of F12. Some rock layers even reach a hardness of F16, and there are numerous fractured zones, making the construction quite challenging.

On November 25, China Hydropower Ninth Engineering Bureau successfully and accurately completed the reverse pull-through of the Yier Technology AT-2000L Raise Borer Machine at the north area of the Yunan Chongwangling mining project.

The project is located in Guiwei Town, Yunan County, Yunfu City, Guangdong Province, and is an important part of the Yunan Chongwangling mining project. The diameter of the expanded ore chute is2 meters, with a depth of 180 meters and an inclination angle of 90°.

The geological layers at the construction site are mainly metamorphic sandstone and gray-white granite, with an average rock hardness ofF12, and some rock layers even reaching F16, with numerous fractured zones, making construction quite challenging.

The AT-2000L Raise Borer Machine was still able to maintain stable operation, ensuring the accuracy and efficiency of the drilling.

The construction location of this shaft is at the mountain top, using a surface-cast concrete foundation and installing a gantry.The AT-2000L Raise Borer Machine is driven by a diesel engine to move to the surface concrete position, where the drilling machine's top support contacts the gantry to form a force point, ensuring the stability of the drilling machine during construction and preventing displacement, which also saves the work of fixing the drilling machine's shoe plate to the surface I-beam.

To ensure construction accuracy and safety, our after-sales engineer Yi Xuanfei used a professional level protractor to strictly verify the verticality of the drilling frame, ensuring that the angle with the ground accurately reaches90°, which is particularly important for ensuring the inclination of the guide hole and expansion operations.

The entire drilling operation process went through multiple stages. FromOctober 6 to 18, the project team completed the guide hole operation in 13 days, with an average guide hole rate of 13.8 meters per day, laying a solid foundation for the smooth completion of the subsequent expansion operations. Then, from October 21 to November 25 (effective working time of 24 days), the average daily expansion rate was 7.5 meters per day, completing the shaft penetration within the scheduled time set by the client.

(Starting guide hole with a tooth roller drill bit)

(Guide hole debris removal)

(Shaft completion)

The successful penetration of this ore chute has created favorable preconditions for the mining operation.

In this project, Yier Technology not only assigned after-sales engineers to provide on-site service and guidance throughout the process but also actively assisted the mining unit in personnel training.

Through systematic training and practical exercises, two operators quickly mastered theoperating skills of the AT-2000L Raise Borer Machine, laying a solid foundation for the future autonomous operations in the mining area.

Compared to traditional hoisting methods, the Raise Borer Machine operates more efficiently and safely, is easy to operate, has fast mechanization speed, can work continuously, and reduces the labor intensity of operators; it uses a rolling cutter for rock breaking, causing minimal damage to the surrounding rock, resulting in smooth shaft walls and good engineering quality, which is beneficial for the construction of ore chutes, ventilation shafts, and drainage shafts.

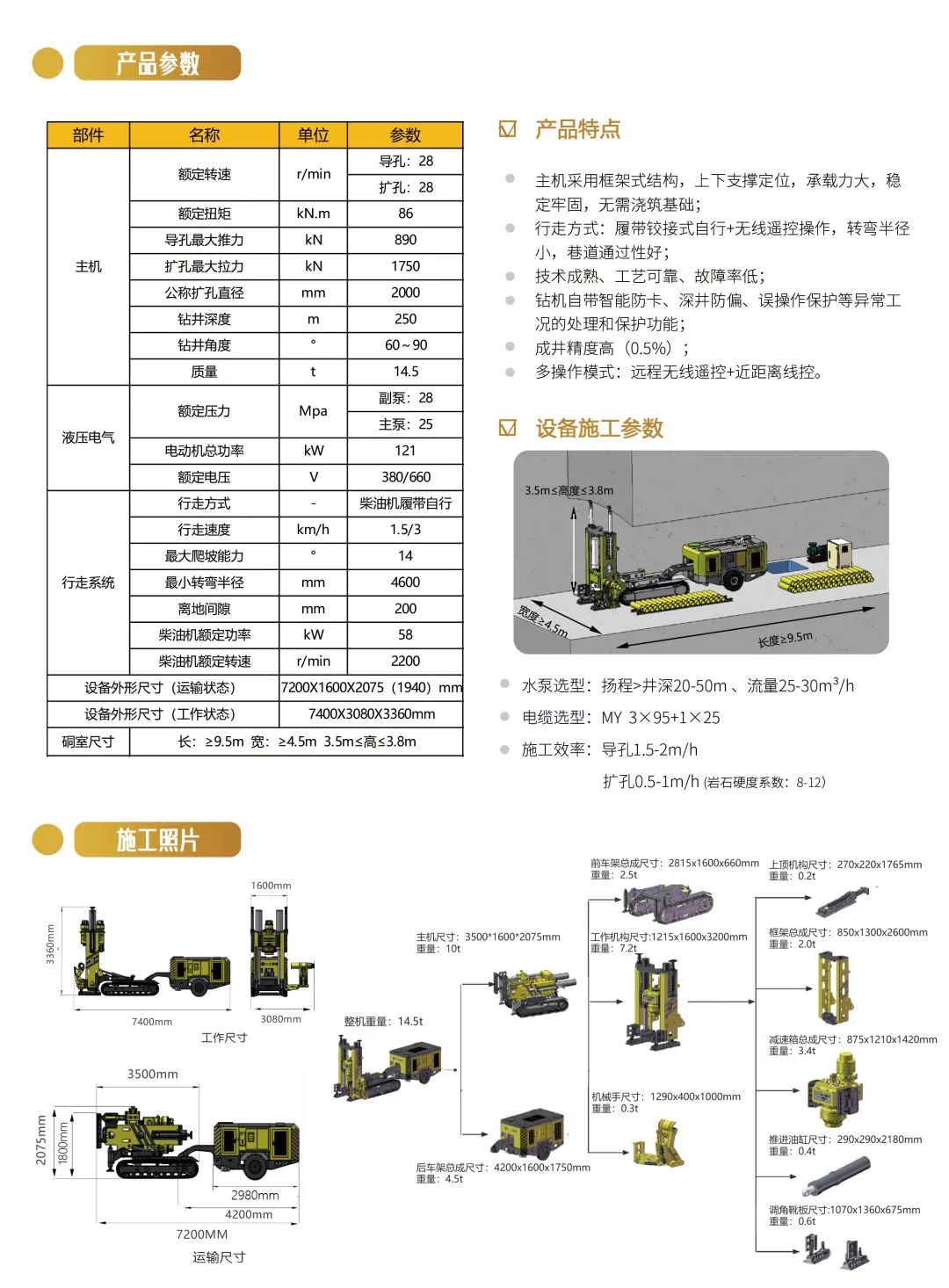

The AT-2000L Raise Borer Machine was developed and designed by our company in response to the new characteristics of underground mining processes in China, integrating the advantages of the existing rail wheel-type drilling technology. This model optimizes the original drilling parameters and uses system integration technology to design a lower overall size, with the walking part using a tracked trailer, transforming the longer solid vehicle body into a center-hinged steering, combined with remote control operation, allowing for a small turning radius, flexible movement, high safety, and better adaptation to the development needs of domestic mines. Everyone is welcome to visit Yier Technology to learn more.

Everyone is welcome to visit Yier Technology to learn more.

Related News