undefined

Set sail across the "Four Seas"! Yier Technology's Overseas After-sales Model and Case Sharing

Release time:

2025-09-10

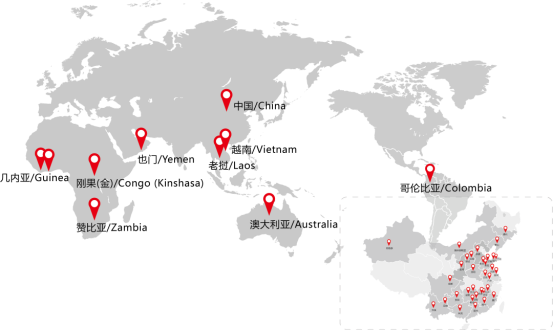

The equipment of Hunan Yier Mining Technology Co., Ltd. has been exported to multiple countries and regions. While overseas sales efforts continue to advance, the overseas after-sales service system is also being continuously improved. The existing overseas after-sales service system includes pre-sale training in China and on-site after-sales project services, which can be emphasized differently depending on the specific project. Several practical cases have demonstrated the company's successful after-sales service practices in Africa, South America, the Middle East, Australia, and Southeast Asia.

The equipment of Hunan Yier Mining Technology Co., Ltd. has been exported to multiple countries and regions. While continuously advancing overseas sales, the overseas after-sales service system is also being constantly improved. The existing overseas after-sales service system includes pre-sale training in China and on-site after-sales project services, which can be emphasized differently according to the specific project situation. Several practical cases have demonstrated the company's successful after-sales service practices in Africa, South America, the Middle East, Australia, and Southeast Asia.

- Overseas After-Sales Model

As of August 2025, Hunan Yier Mining Technology Co., Ltd. (hereinafter referred to as "Yier Technology") has successfully operated 12 overseas equipment cases.

1.1 Pre-Sale Skills Training

During equipment assembly and commissioning, Yier Technology provides customers with comprehensive pre-sale training services. Customers can arrange for operators to come to our workshop to participate in assembly and commissioning. We arrange engineers to be fully responsible for training on technical principles, key component assembly, system debugging, equipment maintenance, and common fault handling. The specific arrangements are as follows:

(1) Workshop Learning. ① Yier Technology assigns assembly engineers to lead trainees in participating in equipment assembly, commissioning, and acceptance work to familiarize them with the production process, installation procedures, and commissioning flow; ② Yier Technology assigns hydraulic, electrical, and structural engineers to teach equipment hydraulic, electrical, and structural knowledge in the workshop, enabling trainees to have a detailed and comprehensive understanding of the equipment's working principles, core configurations, maintenance, and usage requirements;

(2) Conference Room Learning. Yier Technology assigns the after-sales manager to explain case studies in the conference room regarding equipment working chamber size, water and electricity configuration, safety operation procedures, daily maintenance standards, and common geological problem identification and handling;

(3) On-Site Learning. Yier Technology arranges trainees to intern at domestic mines, hydropower stations, tunnels, and other project sites, arranging tasks such as pilot hole/reaming, erecting/collecting machines, hanging/removing cutter heads, to gain on-site equipment operation experience.

Through the above training content, it ensures that customer operators can fully master equipment operation, maintenance, and safety management, improving construction efficiency and safety.

The above pre-sale training duration can generally be controlled between 7 to 30 days depending on the actual situation of customer employees (whether they have relevant experience/history); if the customer has suitable employees needing focused training, they can also be placed at our company's construction project site for 2 to 3 months of practical training, fully participating in project construction and equipment operation, training employees to operate independently in the shortest time.

1.2 After-Sale On-Site Service

After-sales service can be flexibly adjusted and arranged according to the actual needs of customers, mainly divided into three modes:

Mode 1: Customer mainly operates and maintains independently, with our company providing online support as auxiliary.

Condition ①: Comprehensive pre-sale training. Customers arrange employees with rich experience in operating related or similar equipment (this condition is very important and is the basis for adopting "Mode 1") and excellent learning and comprehension abilities to study at our company. After comprehensive training in our workshop and on-site, they are familiar with the equipment and can operate and maintain it independently without the need for our after-sales engineers to provide on-site service, only requiring online technical support later;

Condition ②: Our company provides a complete tool kit with the main machine. This includes spare parts kits, tool kits, maintenance kits, as well as equipment operation tutorial videos (recorded by our after-sales engineers, bilingual in Chinese and foreign languages), equipment operation manuals (Chinese and foreign languages), equipment instructions (Chinese and foreign languages), equipment maintenance manuals (Chinese and foreign languages), equipment spare parts manuals (Chinese and foreign languages), and other usage materials;

Condition ③: Our company has established detailed BOM lists and safety stock to ensure urgent parts can be air-shipped within 2 to 4 hours;

Condition ④: Our key project team sets up an after-sales service WeChat group. Besides customer employees, the group also includes our after-sales personnel, technical staff, and business personnel to instantly connect project status, understand project progress, respond promptly to emergencies, and prepare spare parts in advance;

Condition ⑤: Our company provides a 24-hour after-sales hotline. During the service period (including rest days and national statutory holidays), a dedicated after-sales engineer maintains 24-hour communication to ensure timely communication, exchange, and parts shipment when equipment faults occur;

Mode 2: We provide on-site service, fully training customer employees during the service period to ensure they can operate independently after the service ends.

In addition to meeting the service terms provided in "Mode 1", we dispatch 1 to 2 experienced after-sales engineers to the project site for full-process guidance after contract signing and equipment delivery.

Our service responsibilities include: from the equipment's arrival at the destination and the start of dump truck operation until the end of after-sales service, all matters related to equipment operation or operation guidance, maintenance, repair, and upkeep to ensure the equipment remains in normal condition.

Our service content includes: technical guidance and training on equipment shaft entry (including cages, horizontal tunnels, inclined shafts, ramps, etc.), roadway transportation (including tracked or trackless), chamber specifications (including size and azimuth), chamber roof stability (whether support is needed), water tank specifications, hoisting anchor rods, equipment foundation, water and electricity supply (including cable specifications, water supply volume, etc.) to ensure readiness for construction.

Our training process includes: technical guidance and training for the entire construction process from equipment positioning, erecting, pilot hole drilling, drill bit removal, cutter head hanging, reaming, machine collection, cutter head removal, ensuring full-process service coverage;

Our service period is no less than 1 or 2 months overseas or based on completing a certain amount of work (for example, guiding the construction of several shafts or accumulating a certain number of meters). The ultimate goal is to fully train the customer's trainees. If the customer needs to extend the after-sales service period, both parties can negotiate further.

Mode 3: We provide long-term paid on-site technical services as the main service, with customer assistance as auxiliary.

If customers purchase our equipment and have very high standards for on-site construction services or lack suitable trainees, we can also provide long-term paid on-site technical services. Specifically, we assign experienced after-sales engineers to be stationed at the customer's site, directly leading customer employees in long-term production service. The service period can be one year or even longer, ensuring project completion or that other employees of the client can fully learn and operate independently.

- Overseas After-Sales Case Sharing

Currently, Yier Technology's equipment has been successfully practiced in Africa, South America, the Middle East, Australia, and Southeast Asia. The overseas after-sales case sharing is as follows:

2.1 Project Situation of AT-4000L Raise Borer Machine in Guinea, Africa

This project is the procurement and service plan for the AT-4000L Raise Borer Machine manufactured by China Railway 18th Bureau Guinea Company, meeting the construction needs of the Kindia tunnel ventilation shaft in Guinea, Africa.

Project Overview:

Model and Quantity: AT-4000L Raise Borer Machine / 4 units;

Location: Kindia Tunnel, Guinea, Africa;

Service Period: The service period covers until the full completion of all 8 ventilation shafts of the project, ensuring worry-free support throughout the project;

Project Details: Diameter 3.5 meters, depths: 418m, 392m, 436.27m, 425.4m, 213m, 195m, 198m, 197m, totaling 8 shafts.

Overseas After-sales Model:

Professional On-site Team: We dispatched an elite team of four senior after-sales engineers—Zhang Jun, Peng Shuai, Yang Jun, and Li Zhixin—to be stationed at the China Railway 18th Bureau project department in Guinea, adopting "Model Three" to provide full-process on-site services;

Full Technical Support: From equipment installation and commissioning, daily operation and maintenance to on-site operational construction, the after-sales engineering team is fully involved to ensure efficient and stable equipment operation; through on-site guidance and hands-on training, they help client engineers master independent operation and usage skills of the AT-4000L Raise Borer Machine, achieving technology transfer and enhancing autonomous operation and maintenance capabilities;

Spare Parts Warehouse: Our company has established a spare parts warehouse for vulnerable and consumable parts at the project department to ensure project continuity;

Unobstructed Language Communication: Considering that communication at the project department is mainly in Chinese with English as auxiliary, translators were arranged in advance to assist coordination, and the after-sales engineering team has been stationed for a long time, basically mastering English communication phrases, enabling smooth communication with local staff.

Case Image Display:

2.2 AT-2000 Raise Borer Machine Project in Guinea, Africa

This project is the procurement and service plan for the AT-2000 Raise Borer Machine manufactured by the contractor China Railway 11th Bureau, meeting the construction needs of the Mamou tunnel ventilation shaft in Guinea, Africa.

Project Overview:

Model and Quantity: AT-2000 Raise Borer Machine / 1 unit

Service Period: The service period covers until the full completion of all 3 shafts of the project, ensuring worry-free support throughout the project;

Location: Mamou Tunnel, Guinea, Africa

Construction Details: Diameter 1.6 meters, depths: 330m, 75m, 238m

Overseas After-sales Model:

Professional After-sales Team: We dispatched senior after-sales engineer Jiao Zhaohui to be stationed at the China Railway 11th Bureau project department in Mamou Tunnel, Guinea, adopting "Model Three" responsible for full-process on-site services;

Technical Training and Transfer: Engineer Jiao is responsible not only for daily maintenance and operation of the equipment but also for on-site guidance to local engineers to master independent operation and usage skills of the AT-2000 Raise Borer Machine, promoting localized inheritance of technical skills;

Language Communication Solution: Considering that communication at the project department is mainly in Chinese with English as auxiliary, the project party arranged professional translators to coordinate with after-sales engineers in advance, and Engineer Jiao, with good basic qualities and education, has basically mastered English communication phrases.

Case Images:

2.3 AT-3000L Raise Borer Machine Project in Zambia, Africa

This project is an efficient shaft construction solution proposed and implemented by TRYING INVESTMENTS LIMITED for the Chambishi Copper Mine (China Nonferrous Africa Mining) in Zambia. The project uses two AT-3000L Raise Borer Machines, leveraging excellent performance and professional services to support deep resource development of the copper mine.

Project Overview:

Model and Quantity: AT-3000L Raise Borer Machine / 2 units

Location: Chambishi Copper Mine Construction Project, Zambia (China Nonferrous Africa Mining)

Construction Details: Diameter 3 meters, depth 100 to 280 meters

Overseas After-sales Model:

Professional After-sales Team On-site: We dispatched senior after-sales engineer Wang Chaoqun to be stationed at the Chambishi Copper Mine construction project department in Zambia, adopting "Model Three", planning to provide full-process on-site services for one year;

Technical Training and Continuous Service: After the one-year service period, due to outstanding performance and company approval, the Zambia project department continued to renew the contract with high salary for one more year, continuing to employ Engineer Wang to serve the shaft construction at the project department, achieving seamless service connection;

Unobstructed Language Communication: Considering that the project department is mainly Chinese with communication primarily in Chinese and auxiliary English, the project party arranged professional translators to coordinate with after-sales engineers in advance, and after living and working locally for half a year, Wang Chaoqun has basically mastered English communication phrases, enabling relatively smooth communication with on-site workers.

Case Image Display:

2.4 AT-4000L Raise Borer Machine Project in Colombia, South America

This case focuses on Beijing Chengli Full Technology Co., Ltd.'s successful introduction and application of the AT-4000L D Raise Borer Machine in the iron mine project in Colombia, South America. The project not only demonstrates the powerful capability of the AT-4000L Raise Borer Machine in large-scale mining but also reflects the excellent abilities of both parties in technical cooperation, after-sales service, and international team collaboration.

Project Overview:

Model and Quantity: AT-4000L D Raise Borer Machine / 1 unit

Location: An iron mine project in Colombia

Construction Details: Diameter 4.1 meters, maximum depth 200 to 600 meters;

Overseas After-sales Model:

Pre-sale Technical Training: Before equipment delivery, the end customer (the mining client) dispatched technical engineers to our company for no less than 15 days of full-process drill rig assembly, maintenance, and operation training to ensure the client can master basic drill rig operation and maintenance skills. Since the dispatched engineers already have experience operating similar equipment, learning and familiarizing with this equipment was very efficient.

On-site Full Guidance: After equipment delivery, adopting "Model Two", we immediately dispatched senior after-sales engineers to the site for no less than one month of full on-site guidance, completing at least one shaft construction service to ensure smooth equipment operation and optimal performance;

Multilingual Communication Support: Given that the project department is entirely foreign personnel, the client specially arranged Spanish translators to coordinate with after-sales engineers throughout, and our engineers are equipped with iFlytek translators to assist daily communication, ensuring barrier-free communication;

Comprehensive Data Support: To assist customers in better using the equipment, our company provides the following detailed materials: equipment operation explanation videos (bilingual in Chinese and English), visually demonstrating the operation process and precautions; equipment operation manuals, user guides, maintenance manuals, and spare parts manuals (all provided in Chinese and Spanish versions), ensuring that customer technicians can consult them anytime for accurate operation and maintenance of the equipment.

Case Image Display:

2.5 Congo (DRC) Africa AT-3000 Raise Borer Machine Project Situation

This case is an innovative practice by Gansu Cangsheng Engineering Company in successfully introducing and applying the AT-3000 Raise Borer Machine in the Congo (DRC) project of Gansu Jinchuan Group.

Project Overview:

Model and Quantity: AT-3000 Raise Borer Machine / 1 unit

Location of Use: Congo (DRC) project of Gansu Jinchuan Group

Construction Situation: Diameter 3 meters, depth 50 to 100 meters

Overseas After-sales Model:

Pre-sales Technical Training: Before equipment delivery, Gansu Cangsheng Engineering Company dispatched experienced technical engineers to our company for no less than 7 days of full-process drill rig assembly, maintenance, and operation training, mainly to familiarize with the equipment and master basic drill rig operation and maintenance skills.

Independent Operation + Maintenance Capability Building: After equipment delivery, after-sales adopted "Mode One"; the customer's operating engineers are Chinese employees with many years of rich experience operating similar equipment. Meanwhile, based on sufficient prior technical training and preparation, the customer team is capable of independently undertaking after-sales service. Although our company did not directly dispatch after-sales engineers to the site, we continuously provide strong support to the project through remote technical support, regular video follow-ups, and spare parts supply.

Case Images:

2.6 Middle East Yemen ATM-1000L Raise Borer Machine Project Situation

This case is an innovative practice by SAFETY SOURCES IMPORT CO. LTD in successfully introducing the ATM-1000L cutting Raise Borer Machine in the Middle East Yemen project.

Project Overview:

Model and Quantity: ATM-1000L Raise Borer Machine / 1 unit

Location of Use: Yemen project site

Construction Situation: Cutting shaft operation with a diameter of 670mm

Overseas After-sales Model:

Pre-sales Technical Training: The customer's operating engineers already have very rich experience with similar equipment. Both parties conducted multiple technical exchanges and communications via "online video conferences," and at the customer's request, we produced bilingual Chinese-English operation videos of the "ATM-1000L cutting Raise Borer Machine" for on-site customer learning.

Independent Operation + Maintenance Capability Building: After equipment delivery, after-sales adopted "Mode One." Based on sufficient prior technical training and preparation, the customer's technical team is capable of independently undertaking after-sales service. Although our company did not arrange direct dispatch of after-sales engineers to the site, we provide strong support to the project through detailed technical materials and online remote support.

Case Images:

The equipment has been fully assembled and was shipped on August 26, 2025.

2.7 Australia ATM-1000 Raise Borer Machine Project Situation

This case is an innovative practice by THE ROCKDRILL COMPANY TY LTD in successfully introducing the ATM-1000 cutting Raise Borer Machine in a key project in Australia.

Project Overview:

Model and Quantity: ATM-1000 Raise Borer Machine / 1 unit

Location of Use: Project site in Australia

Construction Situation: Cutting shaft operation with a diameter of 670mm

Overseas After-sales Model:

Preliminary Technical Training and Acceptance: Before equipment delivery, the Australian customer dispatched experienced technical engineers to our company for no less than 7 days of full-process drill rig assembly, maintenance, debugging, and operation training. After training, Australian engineers conducted a comprehensive acceptance of the equipment to ensure performance met project requirements.

On-site After-sales Service Support: After equipment delivery, after-sales adopted "Mode Two." Our company will dispatch experienced after-sales engineers to the Australian project site to provide on-site service for no less than one month. Regarding language communication: the customer assigned a translator, and engineers carry iFlytek translators to ensure smooth communication. After-sales engineers will track equipment operation status throughout, promptly resolving on-site issues to ensure efficient and stable equipment operation.

Comprehensive Technical Data Support: To assist customers in better using the equipment, our company provides the following detailed technical materials: equipment operation explanation videos (bilingual in Chinese and English), visually demonstrating operation processes and key precautions; equipment operation manuals, user guides, maintenance manuals, and spare parts manuals (all provided in Chinese and English versions), ensuring that user-side technicians can consult anytime for accurate operation, maintenance, and spare parts replacement.

Case Images:

Shipping Notice: The Australian customer will conduct equipment acceptance in the workshop from August 25 to August 30, and shipment will proceed after acceptance.

2.8 Southeast Asia Laos AT-2000 mini Raise Borer Machine Project Situation

This case is an innovative practice of successfully introducing the AT-2000 mini Raise Borer Machine in a potash mine project in Laos.

Project Overview:

Model and Quantity: AT-2000 mini Raise Borer Machine / 1 unit

Location of Use: Potash mine project in Laos

Construction Situation: Diameter 1.5 meters, depth 100 meters

Overseas After-sales Model:

Preliminary Technical Training: Before equipment delivery, Shanxi Huazuan Company dispatched experienced technical engineers to our company for no less than 7 days of full-process drill rig assembly, maintenance, and operation training to maximize training effectiveness.

Localized Construction and Independent Operation & Maintenance: After equipment delivery, the Chinese construction team independently conducted construction. After-sales adopted "Mode Two," and our company dispatched experienced after-sales engineers to the Laos project site to provide on-site service for no less than one month.

Data Support: Equipment operation manual (Chinese), equipment user guide (Chinese), equipment maintenance manual (Chinese), equipment spare parts manual (Chinese).

Remote Technical Support and Emergency Response: Our company has established a 24-hour remote technical support hotline to respond to customer technical inquiries and emergency needs at any time, ensuring timely and effective resolution of issues encountered during equipment operation.

Case Image Display:

2.9 Southeast Asia Vietnam AT-2000L Raise Borer Machine Project Situation

This case is an innovative practice of CTY CO PHAN CO KHI VIET LIEN DOANH collaborating with the Chinese engineering team in applying the AT-2000L Raise Borer Machine in the Thong Son Hydropower Station project in Vietnam.

Project Overview:

Model and Quantity: AT-2000L Raise Borer Machine / 1 unit

Location of Use: Thong Son Hydropower Station project in Vietnam (Chinese engineering team)

Construction Situation: Diameter 2 meters, depth 80 to 150 meters

Overseas After-sales Model:

Preliminary Technical Training: Before the equipment delivery period, although the user did not directly dispatch technical engineers to our company for training, we proactively provided detailed technical research materials, including equipment overview, technical parameters, and key operation points, laying a foundation for the user to familiarize themselves with the equipment in advance.

On-site Service Guidance: After equipment delivery, the after-sales service adopted "Mode Two." Our company dispatched experienced after-sales engineer Jiao Zhaohui to the site to provide full-process service guidance for the construction of two shafts. Engineer Jiao was responsible not only for technical support during on-site construction but also for teaching the user's technical engineers how to operate and maintain the equipment. The service period lasted no less than one month to ensure that the user's technical personnel could independently and proficiently operate and maintain the equipment.

Documentation Support: ① Equipment operation explanation video (in Chinese); ② Equipment operation manual (in Chinese), equipment user manual (in Chinese), equipment maintenance manual (in Chinese), equipment spare parts manual (in Chinese).

Case Images:

Related News