undefined

Yier Technology showcased at the National Phosphorus Resource Development and Utilization Technology Exchange Conference, supporting the high-quality development of the phosphorus chemical industry

Release time:

2025-09-10

From July 4 to 6, 2025, the 5th National Phosphorus Resource Development and Utilization Technology Exchange Conference was grandly held in Yichang City, Hubei Province. Yier Technology showcased multiple core technologies and mining shaft drilling solutions, becoming the focus of the conference and providing important support for the high-quality development of the phosphorus chemical industry.

From July 4 to 6, 2025, the 5th National Phosphorus Resource Development and Utilization Technology Exchange Conference was grandly held in Yichang City, Hubei Province. The conference was jointly organized by Hubei Three Gorges Laboratory, the Engineering Technology Research Center for Green and Efficient Development and Utilization of Phosphate Ore and Its Associated Resources, Wuhan Institute of Technology, Three Gorges University, and other units. It aimed to gather industry wisdom and explore innovative paths for the efficient utilization and green development of phosphorus resources. Yier Technology showcased multiple core technologies and mining shaft drilling solutions, becoming the focus of the conference and providing important support for the high-quality development of the phosphorus chemical industry.

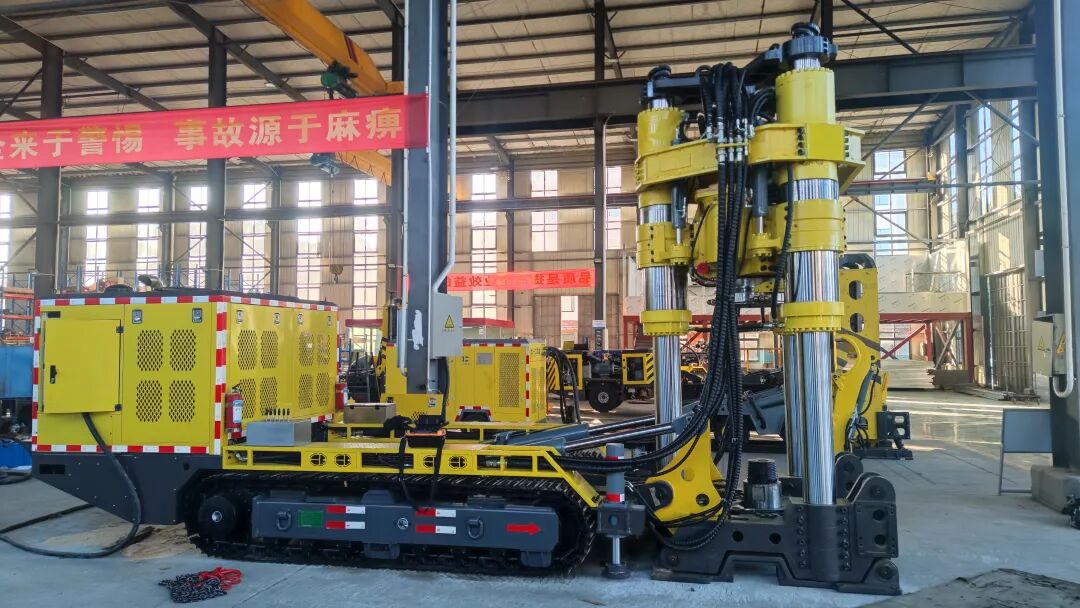

During the exhibition, Yier Technology's booth was crowded with people. The Yier Technology Raise Borer Machine and Down-The-Hole Drilling Machine, as star products, attracted the attention of many mining enterprise representatives and professionals. The mining representatives thoroughly learned about the technical features and application scenarios of the products and conducted in-depth discussions on cooperation opportunities.

Currently, phosphorus ore resources are mostly distributed in deep and complex geological environments. Traditional drilling methods face pain points such as high costs, low efficiency, and high safety risks. Yier Technology launched the AT-2000T, AT-4000L, and other series of Raise Borer Machines, featuring core technologies such as "zero-track free relocation," "omnidirectional drilling," and "high-precision reaming," providing revolutionary tools for deep phosphorus mining.

Zero-track free relocation enhances construction flexibility: Taking the AT-2000T Raise Borer Machine as an example, it uses diesel engine tire self-propulsion and wireless remote control technology, requiring no pre-laid tracks and can quickly adapt to different mine terrains. Compared to traditional rail-wheel drilling rigs, the relocation efficiency is improved by 40%, and precise breakthrough is achieved, significantly optimizing the underground ventilation system.

Omnidirectional drilling and intelligent anti-jamming ensure safety and efficiency: The KQG-150 Down-The-Hole Drilling Machine, as the "golden partner" of the Raise Borer Machine, has 360° all-around drilling capability and can flexibly handle complex geological conditions such as faults and inclusions in phosphate layers. Its equipped automatic anti-jamming system allows the rig to maintain efficient operation under hard rock conditions while reducing maintenance costs.

Multi-mode reaming meets diversified needs: Yier Technology's pioneering ATM-1000L cutting groove Raise Borer Machine integrates deep hole drilling, upward positive reaming, downward positive reaming, and downward reverse reaming functions. It can quickly build cutting grooves without the need for concrete foundation pouring, simplifying the construction process.

In the future, Yier Technology will continue to break through resource bottlenecks through technological innovation, empower green mines with intelligent equipment, and cultivate new quality productivity for the industry.

Related News