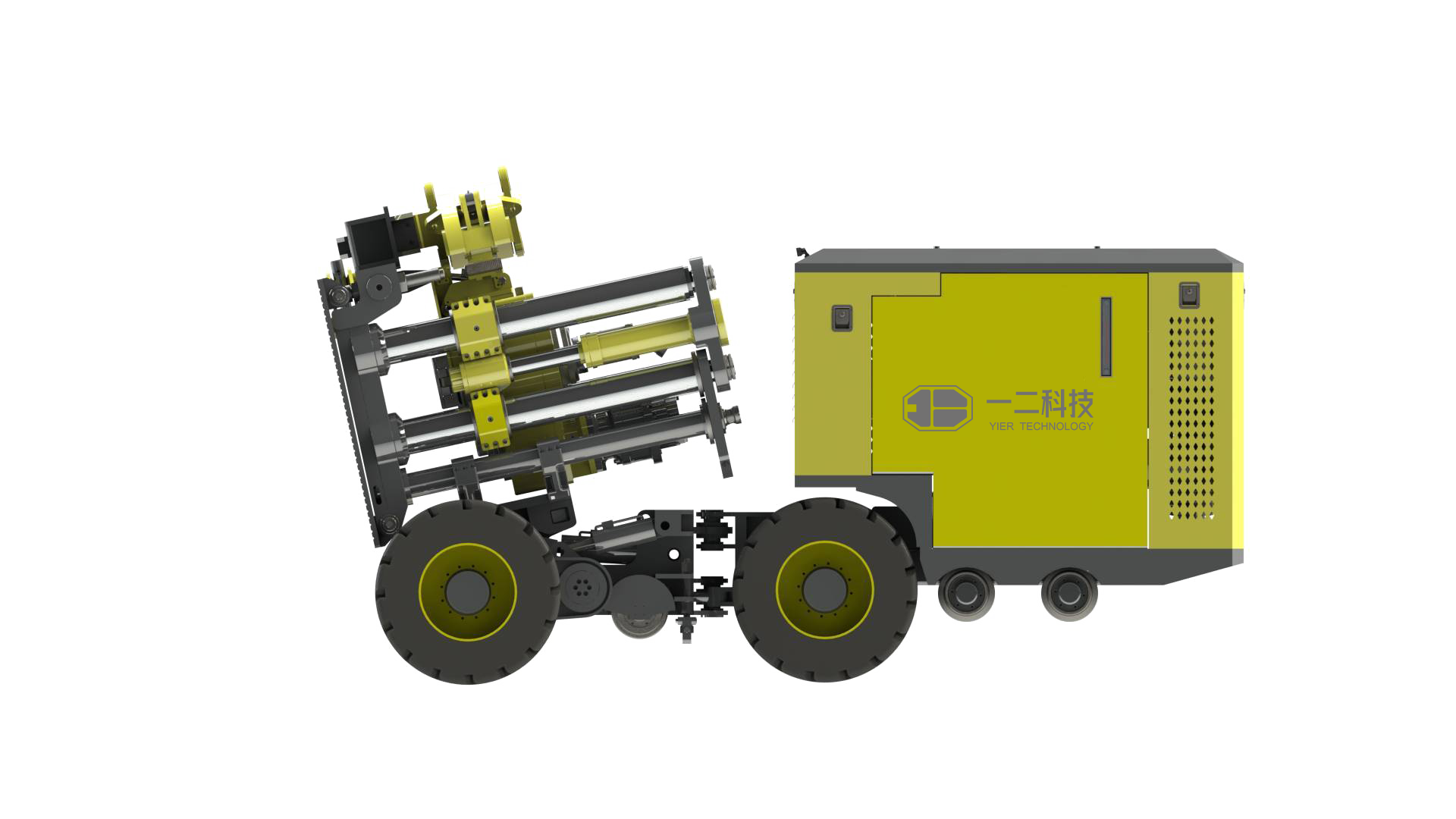

AT-2000T (mini) Raise Boring Machine

Key words:

Classification: Tian anti-well drilling rig

AT-2000T (mini) Raise Boring Machine

The AT-2000T Raise Borer Machine is a miniature overhead drilling rig developed specifically to meet the unique challenges of China's small and medium-sized rail/roadway mine cage systems—characterized by small dimensions, narrow transportation channels, and low working spaces. Featuring a modular design, it offers two versatile transportation options: self-propelled on tires or towed along tracks. Additionally, its convenient positioning system and rapid disassembly capabilities make it perfectly suited to the evolving needs of China's smaller and mid-sized mines.

Product Features

(1) Small in size and easy to transport. Our company produces the AT-2000 miniRaise Boring Machine, which boasts the smallest size among similar products both domestically and internationally.

(2) Remote-controlled all-in-one self-propelled unit. Compared to non-integrated drilling rigs, it reduces the numerous hassles and inevitable errors caused by the disassembly and reassembly process. During travel, the rig is powered by a diesel engine, while during drilling operations, it switches to an electric motor (380V). When transporting over long distances on roads by loading onto trucks, the rig can be remotely controlled to drive directly onto the vehicle—eliminating the need for crane assistance altogether. This design significantly enhances relocation efficiency, lowers labor intensity, and minimizes equipment assembly-related failures.

( 3) Hydraulic wheel-hub four-wheel-drive articulated chassis with wireless remote control for locomotion. Small turning radius, strong maneuverability, and excellent mobility.

(4) Two transportation methods: tire self-propelled and rail drag. This model enables convenient transportation in both rail-based and non-rail mining environments by switching between rail wheels and tires.

(5) A convenient drilling positioning aid. This model achieves vertical movement of the entire drilling frame by operating a mechanism that allows the front wheels to float up and down. Combined with the action of the pitching cylinder, it enables forward and backward tilting, making it possible to perform walking-over-hole operations. Additionally, an independently controlled top-support cylinder ensures precise and rapid positioning, significantly simplifying the challenge of drill rig alignment.

(6) The host and the walking chassis feature a quick-disassembly function. This model's main unit is connected to the walking chassis via a quick-connect device, allowing for easy separation simply by unlocking with a hydraulic cylinder. This eliminates the time-consuming and labor-intensive process of disassembling, transporting, and reassembling when relocating the equipment becomes challenging.

(7) Simple operation and high safety and reliability. Employing fully mechanized construction and remote wireless control operation, the system features functions such as parameter acquisition and processing, abnormal condition alarms, and protection against misoperations—effectively preventing failures and risks like stuck drills, deviations, and rod drop caused by human error. The remote control operation includes a wired interface, allowing seamless transition to manual control in extreme situations to ensure safety.

Inquiry