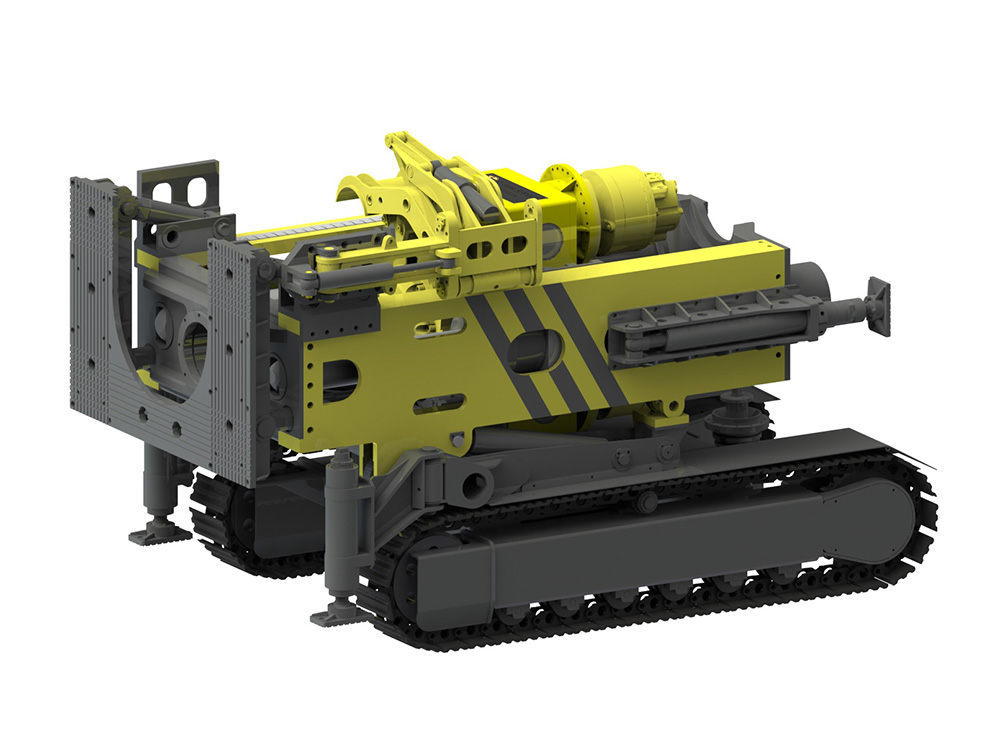

AT-2000L Raise Boring Machine

Key words:

Classification: Tian anti-well drilling rig

AT-2000L Raise Boring Machine

The AT-2000L was developed and designed by our company specifically to meet the new characteristics of current underground mining processes in China, building upon the proven advantages of our existing rail-mounted wheeled drilling rig technology. While optimizing the original rock-drilling parameters, this model incorporates system integration technology to achieve a lower-profile design for the overall machine dimensions. Its undercarriage features a tracked trailer system, transforming the relatively long rigid vehicle body into a centrally hinged steering mechanism. Combined with advanced remote-control operation, the rig boasts a compact turning radius, exceptional maneuverability, and enhanced safety—making it perfectly suited to the evolving needs of China's mining industry.

Main Technical Features

1) Utilizes a low-speed, high-torque motor and full-hydraulic drive technology;

2) Features a reasonable structure and simple operation;

3) Employs a tire-type chassis walking system, offering strong traction and excellent hill-climbing capability;

4) High torque, stepless speed adjustment for drilling;

5) Compact overall design, simple and convenient for installation;

6) High hole-forming accuracy;

7) Strong capabilities and seamless transitions;

8) Excellent impact resistance and reliable operation;

9) Capable of meeting operational requirements for higher rock hardness and large-diameter shafts;

10) Employs a modular design for easy maintenance and replacement;

11) Advanced wireless remote control technology can be employed, enabling safe and convenient operation over long distances and from multiple angles.

Main application areas

AT-2000L Equipped with advanced drill pipe handling robotic arms, the system eliminates the need for an auxiliary crane. These arms can directly pick up drill pipes from the ground and position them precisely at the loading/unloading station—requiring virtually no manual intervention, which significantly enhances safety and ensures smoother, more reliable operations. Moreover, the entire process can now be completed by a single operator simply by pressing a few buttons, dramatically reducing workers' physical strain. Additionally, the system features a brand-new hydraulic system that incorporates cutting-edge hydraulic integration technology, streamlining the layout of hydraulic pipelines. A load-sensing, overflow-free design minimizes heat generation and energy waste, further boosting the overall stability of the hydraulic system. Finally, the use of state-of-the-art hydraulic components paired with high-quality imported seals effectively prevents leaks across all system parts, ensuring long-lasting performance and reliability.

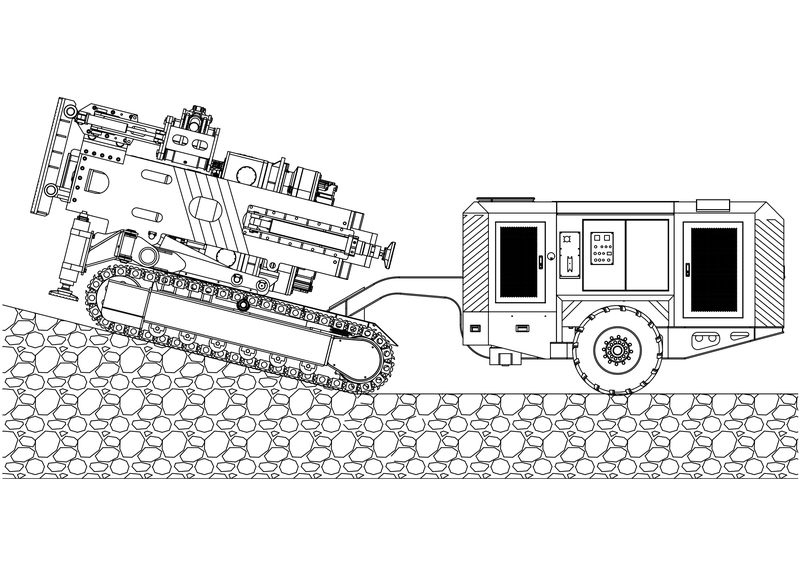

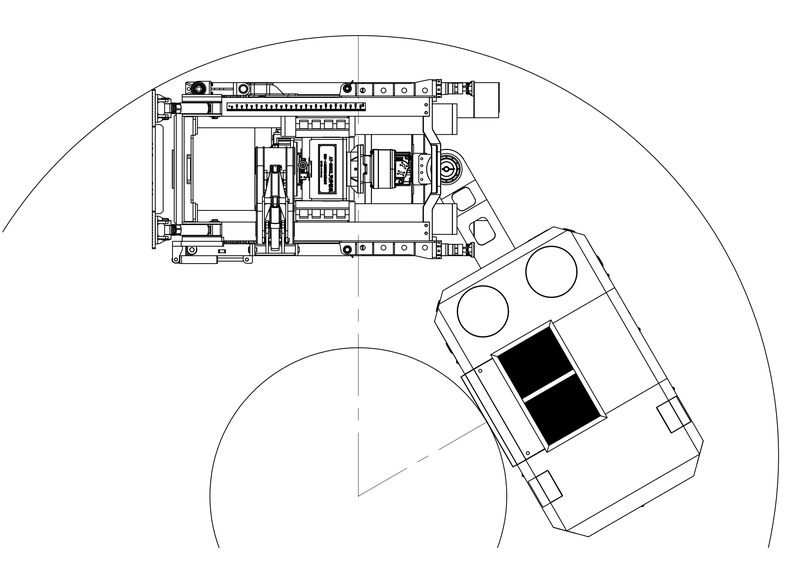

The walking system employs a tracked trailer, transforming the longer solid vehicle body into a center-hinged steering mechanism. Overall, this vehicle’s mobility and external dimensions closely match the tunnel requirements for a 2m³ underground loader. Its soft-terrain control system utilizes load-sensitive proportional control technology, enabling smoother, stepless speed adjustments during operation while minimizing inertial shocks caused by starting and stopping. Additionally, its high-precision control allows for minute displacement movements, enhancing both safety and comfort during operation. Furthermore, the inclusion of time-tested, proven features significantly reduces the likelihood of malfunctions.

Self-Propelled Vertical (Counter) Shaft Drilling Rig Climbing Slope Diagram

Self-Propelled Vertical (Counter-)Shaft Drilling Rig Steering Diagram

Inquiry