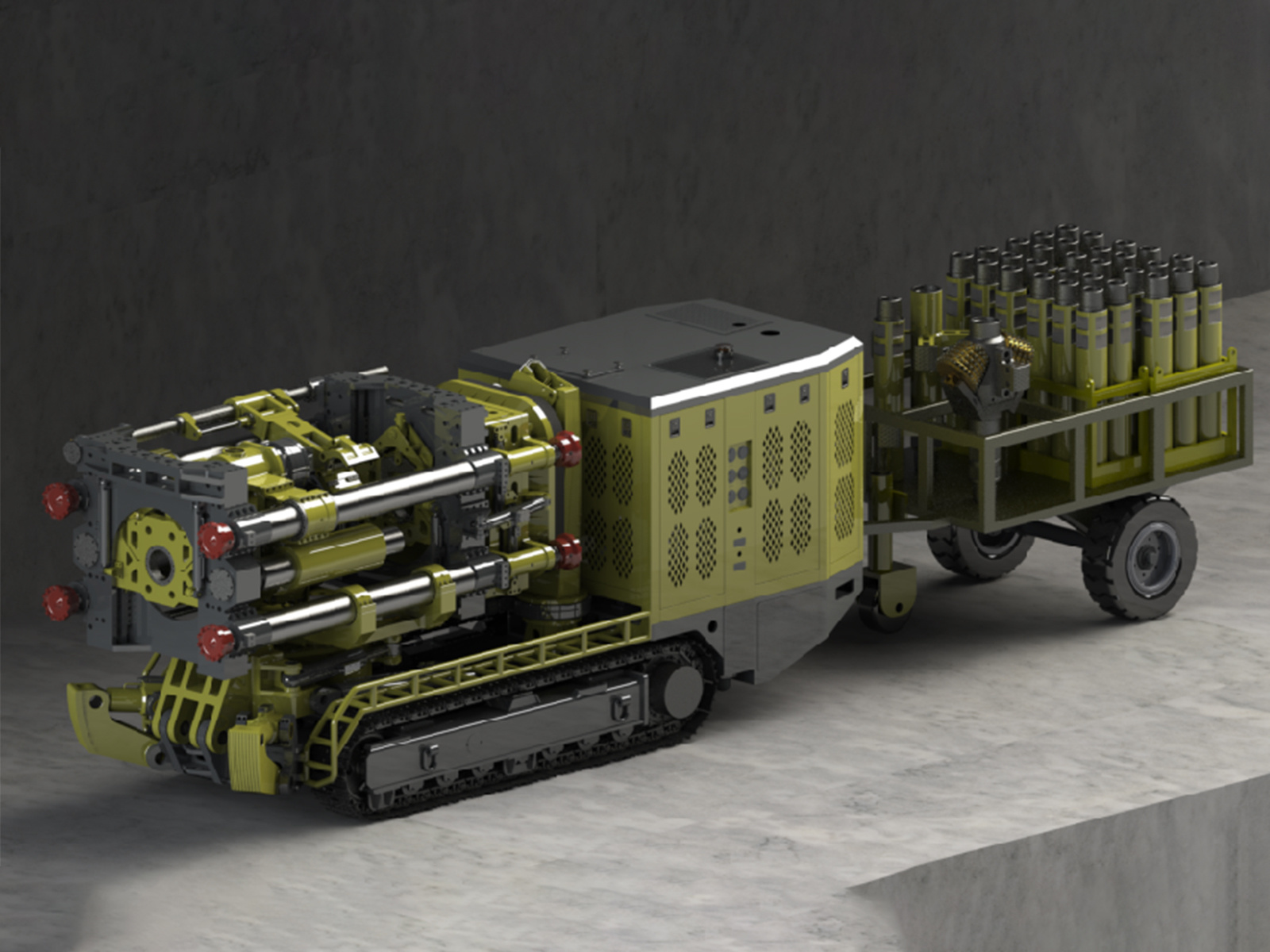

ATM-1000L Underground Mine Cutting Groove Raise Boring Machine

Drilling Depth:Upward: 60m、Downward: 200m

Travel Mode :Diesel engine-driven, crawler-mounted self-propelled

Operation Mode: remote wireless remote control operation

Key words:

Classification: Tian anti-well drilling rig

ATM-1000L Underground Mine Cutting Groove Raise Boring Machine

The ATM-1000L Blind Raise Borer Machine (commonly known as the "Cutting Slot Raise Borer Machine") is the first multifunctional Raise Borer Machine developed by Hunan Yier Mining Technology Co., Ltd., specifically designed for construction of cutting slots and shafts. Compared to similar products on the market, it features high mobility, multifunctionality, and excellent production efficiency, simplifying the preparatory work required for the operation of traditional Raise Borer Machines, eliminating the need for pouring concrete foundations. Its drilling modes include deep hole drilling, upward positive expansion, downward positive expansion, and traditional Raise Borer Machine's downward reverse expansion, meeting the development needs of various underground mines in China.

Product Features:

(1) Dual-purpose: can be used for upward blind well construction and downward reverse well construction.

(2) The smallest equipment size, simple operation, and flexible and convenient relocation.

(3) Walking method: crawler self-propelled + wireless remote control operation.

(4) Multiple gear selections, can automatically match suitable operating parameters according to different hole diameters and rock layer conditions.

(5) The drilling machine is equipped with intelligent anti-jamming, deep well deflection prevention, and misoperation protection functions for handling and protecting against abnormal conditions.

(6) Multiple operating modes: remote wireless control + close-range wired control + onboard control.

(7) The drilling machine is equipped with an auxiliary positioning system for precise location of the opening.

(8) Comes with a drill rod transport vehicle.

| Components | Component Name | Unit | Raise-boring | Raise-boring | ||

| Main Machine |

Nominal Pilot Hole Diameter | Mm | --- | 216 | ||

| Nominal Reaming Diameter | Mm | 1000 | 1000 | |||

| Rated Speed | Rpm | 0-20 | Pilot Hole:0-25 | |||

| Reaming:0-11.5 | ||||||

| Rated Drilling Depth | m | 60 | 120 | |||

| Maximum Pilot Hole Thrust | Kn | --- | ≥490 | |||

| Maximum Reaming Thrust | Kn | ≥880 | ≥880 | |||

| Drilling Angle | ° | 60-90 | ||||

| Rated Torque | Kn.m | ≥65 | ||||

| Transportation Dimensions (L-w-h) | Mm | 5700*1660*2380(Non-Detachable Height) | ||||

| Working Dimensions (L-w-h) | Mm | 6865*2550*3650(Minimum Working Height) | ||||

| Noise | Db(A) | ≤85 | ||||

| Quality | t | 23.6 | ||||

| Electrical | Rated Pressure | Mpa | Main Pump:35 Auxiliary Pump: 26 | |||

| Rated Motor Power | Kw | Main Pump:75 Auxiliary Pump: 22 | ||||

| Rated Voltage | V | 380 | ||||

| Effective Volume of Oil Tank | L | 400 | ||||

| Hydraulic System Cooling Method | Non-Circulating Fresh Water Cooling | |||||

| Traveling Mechanism | Travel Mode | --- | Crawler | |||

| Travel Speed | Km/h | 1st Gear | 2nd Gear | 3rd Gear | ||

| 1.05±0.1 | 1.25±0.1 | 2.40±0.2 | ||||

| Km/h | 1st Gear | 2nd Gear | ||||

| 1.05±0.1 | 1.25±0.1 | |||||

| Gradeability | ° | ≥14 | ||||

| Turning Radius | Mm | ≤3500 | ||||

| Minimum Ground Clearance | Mm | ≥200 | ||||

| Diesel engine Rated Power | Kw | 96 | ||||

| Diesel engine Rated Speed | R/Min | 2200 | ||||

| Boom Load | Minimum Arm Length | 1.67m | Maximum arm length | 4.75m | ||

| Maximum Load | 2155kg | Maximum Load | 675kg | |||

Inquiry