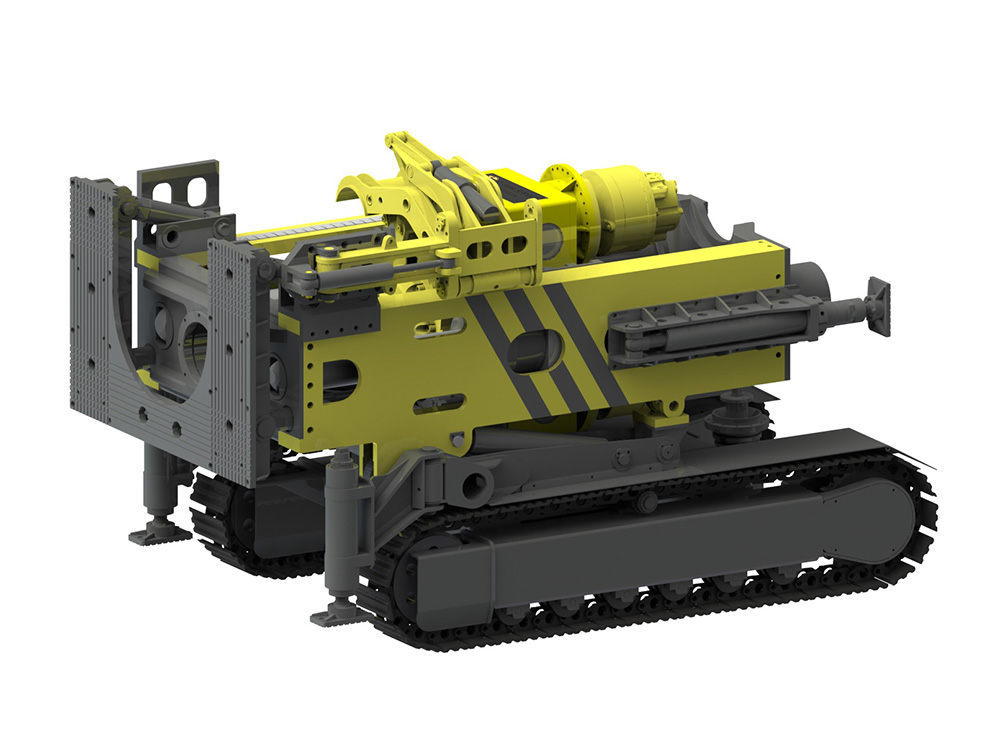

AT-2000L Raise Borer Machine

Drilling Depth : 250m

Travel Mode :diesel engine-driven, crawler-mounted self-propelled

Operation Mode: remote wireless remote control operation

Key words:

Classification: Tian anti-well drilling rig

AT-2000L Raise Borer Machine

Main Technical Features

1) Uses low-speed, high-torque motors and fully hydraulic drive technology;

2) Reasonable structure and easy operation;

3) Adopts a tire-type chassis walking system, with strong traction and climbing ability;

4) High torque, infinitely variable speed drilling;

5) Overall compact design, simple and convenient installation;

6) High hole formation accuracy;

7) Strong passing ability, convenient transition;

8) Good impact resistance, reliable operation;

9) Can adapt to higher rock hardness and large diameter shaft operation requirements;

10) Modular design for easy maintenance and replacement;

11) Advanced wireless remote control technology can be selected for safer and more convenient long-distance, multi-directional operation.

Main Application Areas

AT-2000LEquipped with advanced drill rod loading and unloading robotic arms, eliminating the need for an auxiliary crane, it can directly grab the drill rod from the ground and deliver it to the unloading position, requiring minimal manual intervention, enhancing safety and stability. Only one person is needed to operate the buttons to complete the entire operation process, greatly reducing the labor intensity of workers; the new hydraulic system and the application of hydraulic integration technology simplify the hydraulic pipeline structure, and the load feedback type without overflow design reduces system heating and energy consumption, thereby improving the stability of the hydraulic system. The use of advanced hydraulic components and imported seals greatly avoids leakage of various components.

The walking part adopts a tracked walking trailer, transforming the longer solid vehicle body into a center-hinged steering method. The overall passing ability and dimensions of this vehicle are very close to the tunnel requirements of a 2m3 underground loader. The walking soft characteristic control uses load-sensitive proportional control technology to better achieve infinitely variable speed during the process, reducing the inertial impact of starting and stopping. High-precision control of micro-shifts makes operation safer and more comfortable. The mature functional configuration used for many years greatly reduces the occurrence of faults.

| Components | Component Name | Unit | Parameter |

| Main Machine | Rated Speed | r/min | Pilot Hole:28 Reaming:28 |

| Rated Torque | KN.m | 86 | |

| Maximum Thrust Of Pilot Hole | kN | 890 | |

| Maximum Reaming Pulling Force | kN | 1750 | |

| Nominal Reaming Diameter | mm | 2000 | |

| Drilling Depth | m | 250 | |

| Drilling Angle | ° | 60~90 | |

| Quality | t | 14.5 | |

| Hydraulic & Electrical | Rated Pressure | MPa | Auxiliary Pump: 28 Main pump: 25 |

| Total Motor Power | kW | 121 | |

| Rated Voltage | V | 380/660 | |

| Traveling Mechanism | Traveling Mode | - | Diesel Crawler Self-Propelled |

| Traveling Speed | km/h | 1.5/3 | |

| Maximum Gradeability | ° | 14 | |

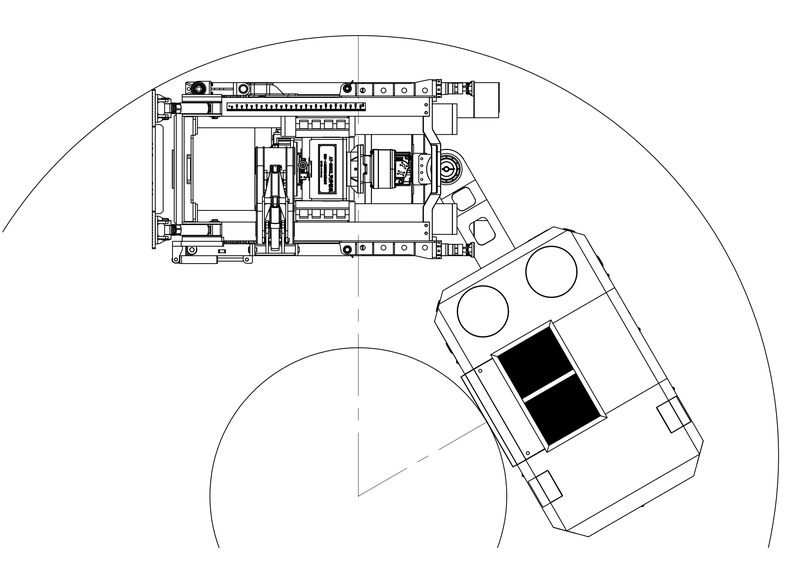

| Minimum Turning Radius | mm | 4600 | |

| Ground Clearance | mm | 200 | |

| Rated Power Of Diesel Engine | kW | 58 | |

| Rated Speed Of Diesel Engine | R/min | 2200 | |

| Equipment Transportation Dimensions (L×W×H) | 7200X1650X2075 (1940) mm | ||

| Equipment Working Dimensions (L×W×H) | 7400X3080X3360mm | ||

| Chamber size(L*W*H) | 9.5m*4.5m*(3.5-3.8)m | ||

Inquiry